Paper phenolic in its most basic form is comprised of layers or paper and resin called laminate. This resin is what holds the paper together and gives it its strength. Paper phenolic laminate is formed when the paper and resin are combined together using heat and pressure. It helps to create a hard and strong substance. This gives an end sheet that can be molded or cut to many sizes, which is why it also used by numerous cord sales.

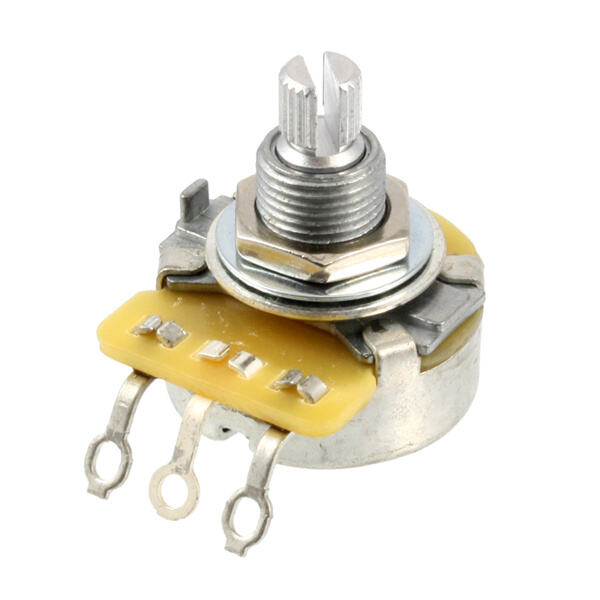

Paper phenolic laminate is more common than you might think, and used in a variety of everyday items! Have you ever seen a circuit board for example? This is one thing made from paper phenolic laminate This is also often used to create electrical insulators, in order to prevent a electricity from leaving where it should not. You'll also discover paper phenolic laminate in knife handles, for the grip and strength required. In fact, it is even used for some musical instruments in order to make them sound nice!

It is certainly painstaking work to produce paper phenolic laminate. First it has the paper which is already soaked in resin, that prepares a surface to stick.apply. Then hot metal plates press the wet paper. The plates would transfer heat to the paper and resin, melting them into a cohesive unit. They quickly and solidify as they are heated together, making an extremely tight bond that combines with other material to from a strong sheet.

After the sheets are prepared, they will have to be chilled. Once they have cooled, the sheets are cut into the appropriate size and shape as needed. These sheets are often dyed or printed in order to make them appealing, and even for certain designs.

Paper phenolic laminate has a lot going for it. To start with, it is very durable and will last a long time which matters for many products. It is also heat resistant so you can safely use it where there are high temperatures. It is also extremely affordable compared to other materials, and thus allows it a great deal of flexibility based upon the application.

However, the use of Paper Phenolic laminate also has some downsides. If it is put under too much pressure, for instance, this could make it crack or break. Whenever using products constructed from this aluminum, keep in mind that. It is also difficult to process as it has high strength and brittleness, making it easy to break when cutting or shaping.

The Advantages If you happen to own anything that is made up of paper phenolic laminate, it means taking good care of the product so as to keep it in optimal condition. Below are some useful pointers concerning the preservation and refurbishment of paper phenolic laminate articles: