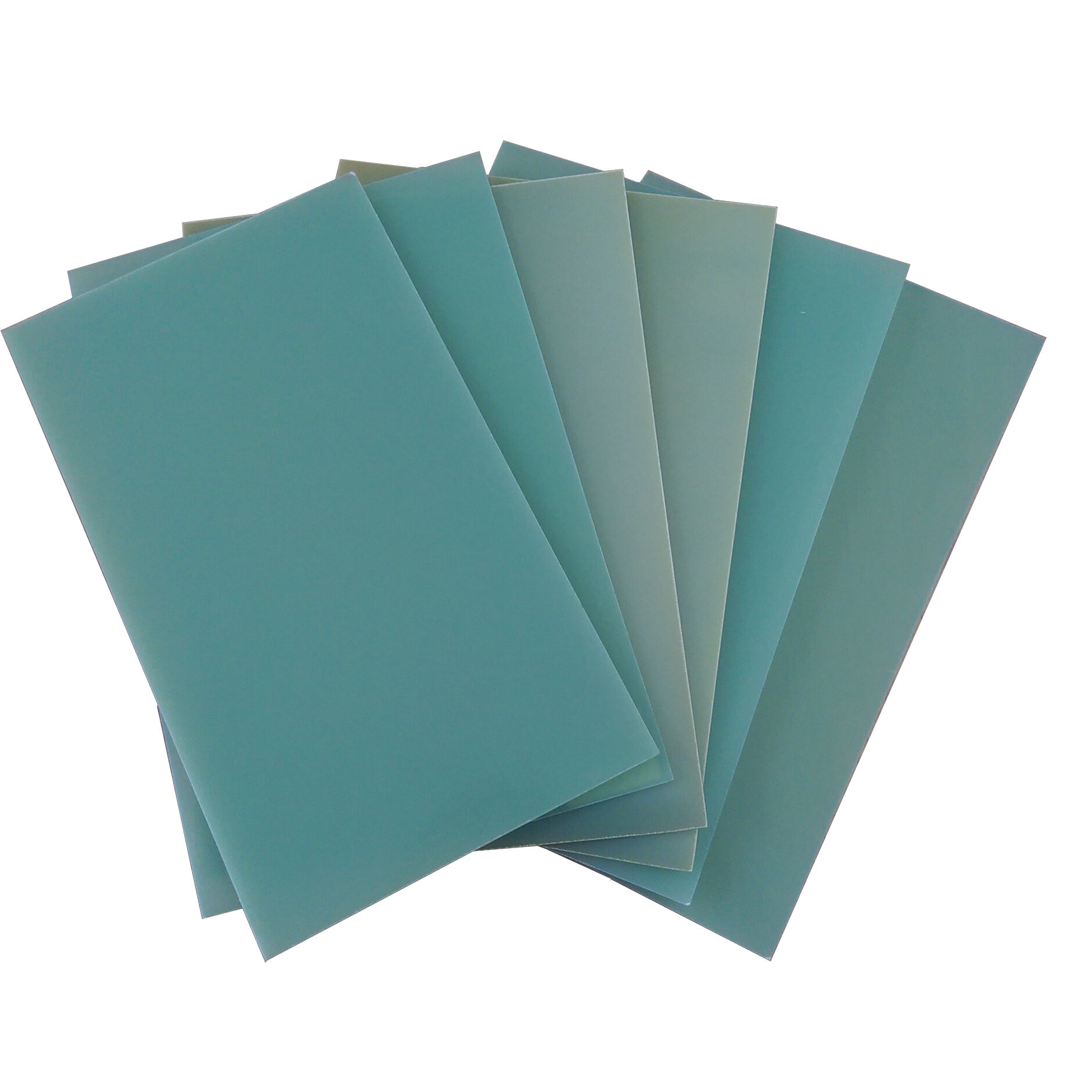

Г10 лист

Произведена је од стаклених влакана као Г10 лист. Склово влакно је супер чврст материјал који је направљен од многих слојева стаклене тканине. Ови слојеви су комбиновани са липилом смолом познатом као епоксична смола. Затим су слојеви преливани под великим притиском што даје G10 листу невероватну чврстоћу. Та снага чини Г10 лист одличним избором за широк спектар пројеката и примена.

Предности Г10 шеа

Г10 лист није само за велике фабрике или индустрије ; такође је невероватно за пројекте за самостално рађење! DIY је скраћеница за "ради сам" и односи се на стварање ствари сами за забаву. G10 лист је лако сећи и обликовати, што значи да можете да га користите да направите све врсте фантастичних ствари. Да ли волите да правите прилагођене ручеве ножева које само одговарају у вашу руку или кабане за аутомобиле са даљинским управљачем који могу да трче и показују како их стварно користити?

-

Најбоље решење за окружење под великим стресом

Још једна најбоља предност листа Г10 је да је лаган. Ово је посебно значајно у тим секторима, као што је индустрија авиона, када се свака унца тежине рачуна. Лаки материјали омогућавају авионима да лакше полете и да троше мање горива, што је боље за животну средину и економију.

-

Непревредна отпорност на хемикалије, топлоту и воду

Г10 Лист 1. избор за тешке задатке То је толико јак и издржљив, може се користити у примене где би други материјали пропали. На пример, Г10 лист се користи у ваздухопловној индустрији за производњу делова авиона и свемирских бродова. Хируршке процедуре и делови морају издржавати екстремне температуре, висок притисак и друге напоре који би могли брзо довести до неуспеха слабијих материјала.

-

Промена у индустрији и инжењерству

Г10 Лист је такође веома отпоран на хемикалије, топлоту и воду. Ова отпорност је оно што га чини идеалним за употребу у ситуацијама у којима су ови елементи присутни. У поморским апликацијама које укључују чамце и друга водена средства, Г10 лист се обично користи за израду компоненти које ће бити у константном контакту са соленом водом. Слатководоотпорна10 Лист ужива у соленој води и из базена изалази најлепша.

Why choose РДС Г10 лист?

-

Поуздана глобална логистика и ланци снабдевања

Подржавамо дугорочна партнерства са морским, ваздушним и железничким превозницима, пружајући флексибилна и ефикасна решења за испоруку како бисмо подржали благовремено глобално испоруку.

-

Услуга усредсређена на клијента и подршка након продаје

Приоритетом за нас су благовремено комуникација, професионална техничка помоћ и одговорна послепродајна услуга како бисмо осигурали безпроблемно искуство и трајно задовољство наших клијената широм света.

-

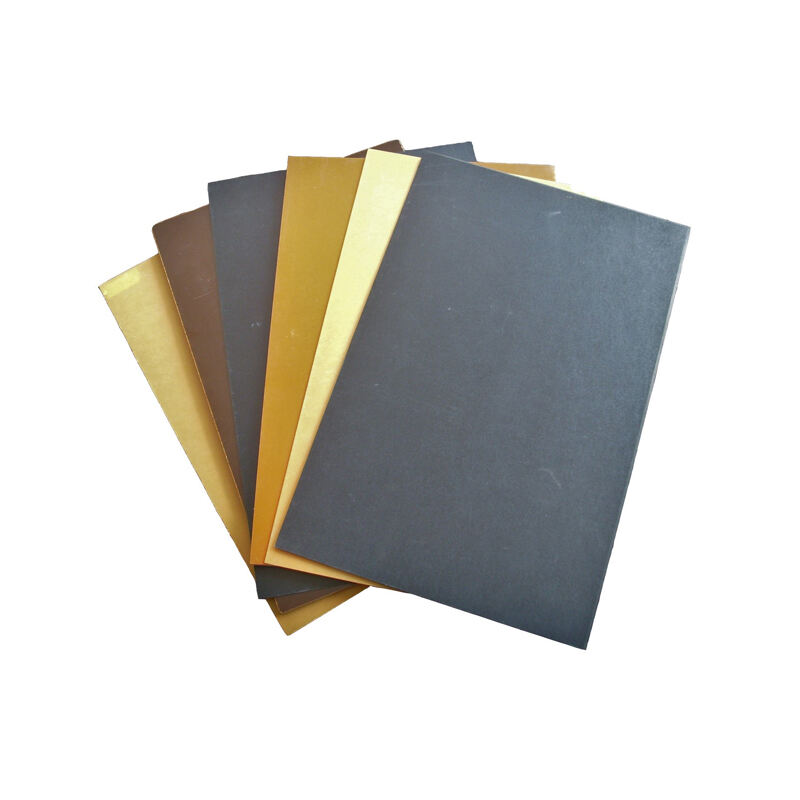

Свеобухватан портфолио изолационих материјала

Као професионални произвођач, нудимо широк спектар изолационих материјала, укључујући стаклово жило, угљенско влакна, памучне тканине и ламинат на бази папира, као и услуге инжекције пластике и производе композитних материјала на основу.

-

Модерна производња и техничка експертиза

Са модерном опремом, напредном технологијом и тимом искусних инжењера, осигуравамо да наши производи стално испуњавају међународне стандарде и различите захтеве за примену.

EN

EN