เนื่องจากวัสดุแผ่นไฟเบอร์กลาส G10 มีความโดดเด่น จึงมีผู้ใช้งานจำนวนมาก แต่ละเส้นใยของมันเป็นชิ้นกระจกเล็กๆ ที่ทำจากซิลิกอนไดออกไซด์หลอมละลายที่ผสมกับเรซิน ซึ่งทำหน้าที่เป็นฉนวนเพื่อสร้าง "ทางนำแสง" เมื่อรวมวัสดุทั้งสองเข้าด้วยกัน จะกลายเป็นวัสดุที่แข็งแรงและทนทานมาก ดังนั้น ในบทความนี้เราจะมาพูดถึงคุณสมบัติที่ดีของแผ่นไฟเบอร์กลาส G10 และวิธีการนำไปใช้ในหลากหลายแอปพลิเคชันในหลายภาคส่วนอุตสาหกรรม

จากประโยชน์ทั้งหมดของแผ่นไฟเบอร์กลาส G10 มีอย่างหนึ่งที่โดดเด่นจนลูกค้าต้องประทับใจ... นั่นคือพลังอันเหลือเชื่อของมัน! ในบางกรณี ยังแข็งแรงกว่าโลหะเสียอีก! ดังนั้น แผ่นไฟเบอร์กลาส G10 เหมาะสำหรับวัตถุขนาดใหญ่และสำคัญมาก เช่น บ้าน สะพาน เป็นต้น เพื่อช่วยให้มั่นใจว่าอาคารเหล่านี้จะยืนหยัดและปลอดภัย อีกสิ่งหนึ่งที่ทำให้แผ่นไฟเบอร์กลาส G10 มีความโดดเด่นคือน้ำหนักเบา ซึ่งทำให้เหมาะสำหรับใช้งานในเครื่องบินหรือรถยนต์ โดยไม่เพิ่มน้ำหนักมากเกินไป การควบคุมน้ำหนักเป็นปัจจัยสำคัญในยานพาหนะเหล่านี้ เพราะยิ่งเบาเท่าไหร่ ก็ยิ่งเคลื่อนที่ได้ง่ายขึ้นและใช้เชื้อเพลิงน้อยลง นอกจากนี้ วัสดุ G10 ยังมีคุณสมบัติเฉพาะตัวที่สามารถต้านทานความร้อนและความนำไฟฟ้าได้ ซึ่งเป็นวิธีที่ดีในการปกป้องสายไฟและอุปกรณ์ที่มีส่วนประกอบไฟฟ้า ทำให้ปลอดภัยสำหรับผู้คนจากการถูกไฟดูด

งานและอุตสาหกรรมหลายประเภทใช้แผ่นไฟเบอร์กลาส G10 เช่น ในวงการก่อสร้าง เป็นสิ่งที่ทำให้อาคารแข็งแรงและคงทนสามารถต้านทานสภาพอากาศรุนแรงได้ แผ่นไฟเบอร์กลาส G10 ถูกใช้ในอุตสาหกรรมรถยนต์เพื่อผลิตรถยนต์ที่มีน้ำหนักเบาและประหยัดเชื้อเพลิง ซึ่งช่วยประหยัดเงินและลดมลพิษ นอกจากนี้ แผ่นไฟเบอร์กลาส G10 ยังถูกนำมาใช้ในอุตสาหกรรมเรือเพื่อสร้างเรือหลากหลายชนิด เรือเหล่านี้มีความแข็งแรงและน้ำหนักเบา ทำให้เคลื่อนตัวบนน้ำได้อย่างสะดวก

SpaceCraft Plane — อุตสาหกรรมอากาศยาน การใช้งานที่น่าตื่นเต้นที่สุดสำหรับแผ่นไฟเบอร์กลาส G10 คือในอุตสาหกรรมการบิน เนื่องจากสามารถผลิตชิ้นส่วนโลหะสำหรับเครื่องบิน จรวด และยานอวกาศบางประเภทได้ นี่คือเหตุผลว่าทำไมพวกเขาจึงยังคงขอแผ่นไฟเบอร์กลาส G10 เพราะวัสดุนี้มีน้ำหนักเบาและมีความแข็งแรงสูง ซึ่งทำให้เครื่องบินและจรวดสามารถเคลื่อนที่เร็วขึ้นหรือบินไกลขึ้นกว่าที่เคยเป็นมา นอกจากนี้แผ่นไฟเบอร์กลาส G10 ยังมีลักษณะเด่นคือทนต่อความร้อนและกระแสไฟฟ้า ซึ่งเหมาะมากเมื่อบินเพราะหากมีปัจจัยใด ๆ เหล่านี้ทำงานผิดพลาด ก็จะเกิดความล้มเหลวในส่วนหนึ่งของระบบ

วัสดุที่สำคัญและมีประโยชน์เป็นอันดับสองคือแผ่นไฟเบอร์กลาส G10 ความต้านทานต่อความร้อนและความสามารถในการป้องกันกระแสไฟฟ้าทำให้โพลิเมอร์นี้สามารถใช้เป็นฉนวนหุ้มสายไฟและชิ้นส่วนไฟฟ้าอื่น ๆ ซึ่งปกป้องพวกมันจากอุณหภูมิสูงหรือต่ำมากเกินไป สิ่งนี้มีความสำคัญอย่างยิ่ง โดยเฉพาะในพื้นที่ที่มีอุปกรณ์ไฟฟ้าจำนวนมาก นอกจากนี้ แผ่นไฟเบอร์กลาส G10 ยังมีความต้านทานต่อการแตกหักได้ดี เนื่องจากมีอายุการใช้งานยาวนาน ซึ่งสามารถปกป้องชิ้นส่วนไฟฟ้าจากการเสียหาย อีกทั้งยังมีน้ำหนักเบา ทำให้ง่ายต่อการทำงานและการจัดการในสนาม

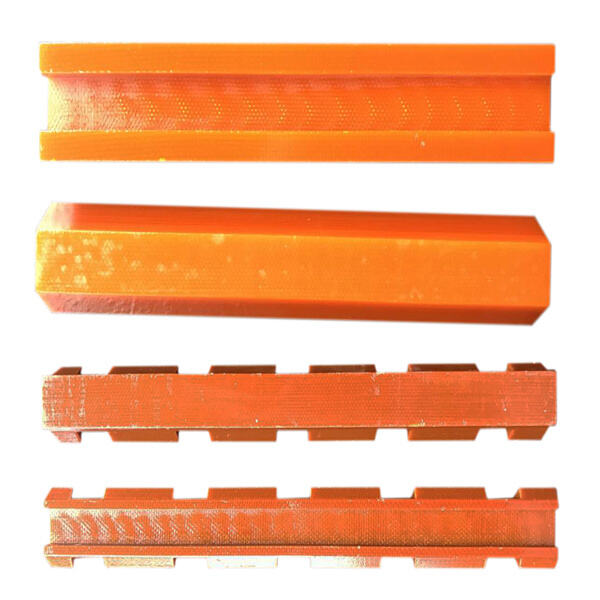

แผ่นไฟเบอร์กลาส G10 เป็นผลิตภัณฑ์ที่มีคุณค่าสูงมากและมอบประโยชน์มากมาย ทำให้เหมาะสำหรับงานที่หนักที่สุด ซึ่งทำให้วัสดุนี้แข็งแรงมากและสามารถทนต่อการสึกหรอได้มากก่อนจะเสียหาย นี่เป็นสิ่งสำคัญโดยเฉพาะในกรณีใช้งานในอุตสาหกรรม เช่น อากาศยาน อุตสาหกรรมรถยนต์ และเรือเดินสมุทร ซึ่งวัสดุจำเป็นต้องทนทาน นอกจากนี้ แผ่นโปรไฟล์ไฟเบอร์กลาส G10 มีความต้านทานต่อความร้อนและกระแสไฟฟ้า จึงถูกนำมาใช้ในหลาย ๆ แอปพลิเคชันที่ต้องการประสิทธิภาพสูง อีกทั้งยังมีข้อดีในเรื่องของความต้านทานต่อการกัดกร่อน ซึ่งช่วยให้มันสามารถอยู่รอดได้แม้ในสภาพแวดล้อมที่เกิดการกัดกร่อน เช่น ในน้ำทะเล