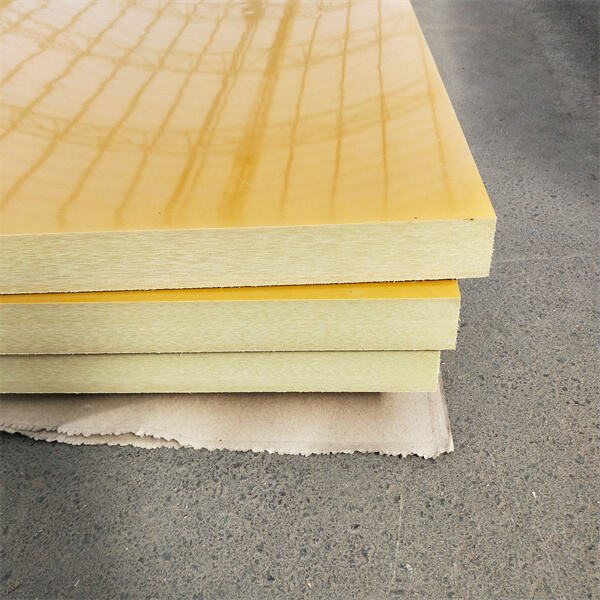

G11 Laminates are an incredibly strong material and can be used in a wide range of industries. Epoxy resin is what gives your composite its fibrous texture, forming a layer over the top and bottom of woven fiberglass cloth. The layers are then pressurized and heated together to fuse into the strong, hard material. Due to lots of different advantages, people are using G11 laminate for the tons of work.

The best part about the G11 laminate is that it has high heat resistance properties. So it remains strong when things get really hot, which makes them a superior iptions for roles in extreme heat. G11 laminate, for instance would be frequently using in electrical equipment due to the fact that it can resist strong electric currents and high temperatures without melting or rupturing. This is interesting from the standpoint that it allows devices to maintain security and proper operation even in difficult environments.

Chemical and moisture resistant:Another benefit of G11 laminate material is that it can fend off chemicals, humidity etc. This characteristic is ideal for industries such as marine and chemicals where materials could either become wet or come in contact with strong substances. Chemical resistanceBecause G11 Laminate is a high-grade epoxy material, it does not corrode when exposed to many chemicals like other materials do. With time, dependability is extremely required in order to help items work well.

G11 Laminate is heat-resistant and chemical-resistant but it also very light weight. This allows the sheet to be easily raised, moved and transported which is particularly useful in industries such as aerospace. Hockey sticks and other sporting goods will benefit from its lightness (you want a bit of snap, right?), while those including higher tensile strength to weight requirements. That lightness also helps the armour all but disappear into an athlete's loadout, so that it can essentially blend in to their look without slowing them down with bulky kit.

The G11 laminate can also be very flexible. It is capable of being molded into numerous shapes and this feature makes it a desirable option for producing personalized parts across some industries. And, it can be formed in to products such as electrical insulators, gears and other components This flexibility is indicative, as it allows manufacturers to tailor-make unique components for their precise needs.

One more vital criterion for excellence of G11 laminate is its long career. This specific material is quite sturdy and this will be able to also last for an extended period without becoming completely broken down. Each of these qualities can make it a great option for industries, and low shrinkage means that the industrial head doesn't need to be replaced as often. G11 laminate is designed to be long-lasting, which ultimately saves companies cash by avoiding the need for frequent replacements.

Engineering and construction are increasingly using G11 laminate. It is mainly applied in electrical insulation machine parts, like generator and transformer insulations, switchgear. It is also used for making parts in the wind turbines, airplanes and boats. It is these properties which make G11 laminate suitable for many applications across both of these industries due to its versatility and strength.