GPO3 is a historical material, availability with high flexibility for many applications, used by many operators. This is the reason it is present in various businesses and occupations. Here we will discuss all the things about GPO3 the wonderful stuff that is facilitating so many sectors to step up and develop. In this article, we will discuss what is GPO3 what makes it a good option for electrical work, where GPO3 is typically used, and what advantages it has.

What is GP2O3?

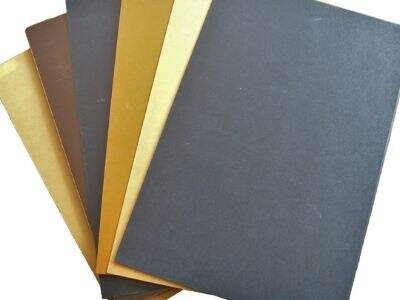

GPO3 is a fiber reinforced as per resin injection & polymers that goes with it. These glass fibers make GPO3 extremely strong as well asg11 laminate excellent for applications involving electricity and machinery. There are a lot of reasons this material is super reliable. It's good atfiberglass sheet electricity, which in turn helps prevent issues like short-circuiting. GPO3 is also rugged enough to take a kick and not getfiberglass reinforced plastic sheet damaged, so it remains in prime condition. It also holds its shape when it heats up, which is super important for many applications. The other good thing about GPO3 is that GPO3 doesn't rust easily. This makes it excellent for use in high-strength situations and rugged environments where other materials can become brittle and corrode.

Why is GPO3 a Good Choice?

A primary motive that makes people pick GPO3 for electrical jobs is its high-temperature suitability. It can remain resilient and effective in extremely high-heat environments. Most materials melt or soften when they heat up, but not GPO3. It has some very special properties that make it resistive to heat very well. This achieves its great performance in many electrical projects where things heat up quickly. GPO3 is also very low smoking and is therefore safe to use. If ever there were to be an issue, though, it won’t produce lots of harmful smoke and so it is a safe option for electrical insulation, as well as, construction.

EN

EN